A boiler which generates steam at pressure greater than 80bar, a temperature of about 500°C, producing, steam more than 250 tons per hour called high pressure boilers. By using high pressure boilers, low grade fuels can be burned easily. High pressure boilers are water tube boilers and use pulverized coal firing. Examples of these boilers are Lamont, Benson, Loeffer and Volex boilers.

Steam Boilers

A boiler is a closed vessel in which steam is generated from the water by applying heat.

Classification: The steam boiler may be classified as

- Fire tube (or) smoke tube boiler.

- Water tube boiler

Fire Tube Boiler

When the hot gas passes through the tubes and the water circulates around the tubes, it is called fire tube boiler.

Examples: Cochran boiler, Lancashire boiler and Locomotive boiler.

Water Tube Boiler

When the water circulates through a large number of tubes and the hot gases pass around the tubes, it is called water tube boiler.

Examples: Babcock and Wilcox boiler, and Stirling boiler.

Advantages of high pressure boilers

- The tendency, of scale formation is eliminated due to high velocity of water through the tubes.

- Light weight tubes with better heating surface arrangement can be used. The space required is less. The cost foundation, the time of erection and cost are minimized due to less weight of the tubes used.

- Due to use of forced circulation, there is more freedom in the arrangement of surface, tubes and boiler components.

- All the parts are uniformly heated. So, the danger of overheating is reduced and thermal stress problem is simplified.

- The difference in expansion is reduced due to uniform temperature and this circulation. There is a greater flexibility in the components arrangement.

- Efficiency of power plant is increased up to 40 to 45%.

Types of High pressure boilers

Lamont Boiler

This boiler works on a forced circulation and the circulation is maintained by a centrifugal pump. This centrifugal pump is driven by a steam turbine using steam from the boiler.

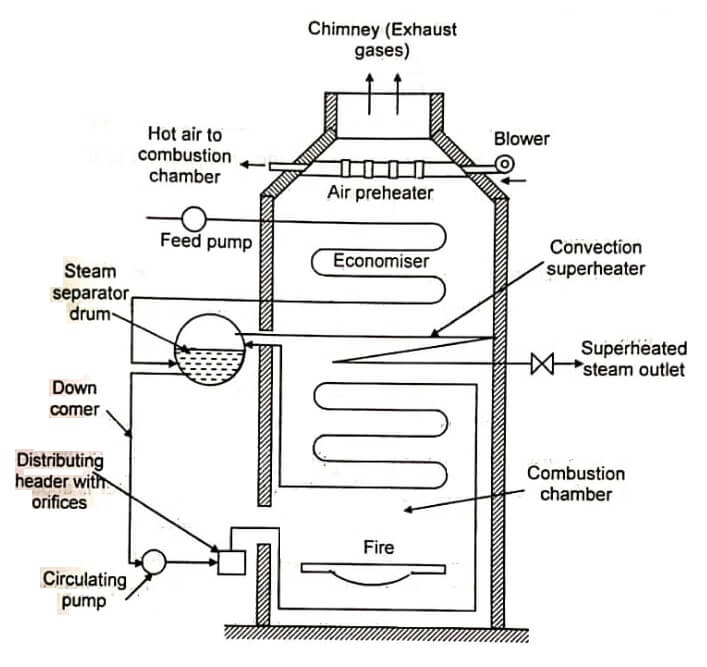

Description: The arrangement of water circulation and different components are shown in fig.

Steam separator drum

It is placed outside the boiler assembly. The drum receives a mixture of steam and water from the evaporator tubes and feeds water from the economizer. The water particles in the steam are separated here.

Water circulating pump

The centrifugal pump is used to draw the water from the drum through the down comer. The pump circulates water by forced circulation and equal to 8 to 10 times the weight of steam evaporated which prevents the overheating of tubes.

Distributing header: It is used to control the flow of water to the evaporator tubes.

Evaporator: It is used to evaporate the water into steam.

Convection superheater: The steam produced in the boiler is in the state of saturated condition. The moisture in the steam will affect the turbine blades and cause corrosion. To avoid this, the super heater is used. It is used to increase the temperature of steam and to improve the efficiency.

Economiser: The main purpose of economiser in the boiler is to preheat the feed water using the exhaust gases flowing out from the boiler to the atmosphere. The preheated water requires only a small amount of heat to be supplied in the boiler. This will increase the efficiency of the boiler. In this. the feed water supplied by the feed pump is heated in the economizer on its way to the steam seperator drum.

Air preheater: It is used to preheat the air by using exhaust gases flowing out from the boiler. The preheated air is supplied to the furnace for combustion.

Working: The feed water, passes through the economizer to the drum, from which it is drawn to the circulation pump. The pump delivers the feed water to the tube evaporating section. The circulating of water is about 8 to 10 times the steam evaporated in the boiler. The steam in the drum is a mixture of steam and water and the steam is drawn through a convection superheater.

The superheated steam is supplied to the prime mover through steam outlet. The working pressure of Lamont boiler is about 170bar and capacity up to 50,000kg of steam per hour at 500°C temperature.

Advantages

- It is forced circulation boiler.

- It gives high working pressure.

Disadvantages:

- The salt and sediment are deposited on the inner surfaces of water.

- It leads to danger of overheating of tubes.

- See More : Control System in Mechatronics

- See More : Stirling Engines

- See More : Steam Power Plant

- See More : Coal Cleaning Equipment

- See More : Hydro Electric Power Plant