Ocean Thermal Energy Conversion (OTEC) Plants convert thermal energy from Ocean water to electrical power. OTEC cogeneration plants deliver electrical energy and fresh water. The unit size of turbine generators is in the range of 10MW to 50MW. The plant ratings are of 50MW and 100 MW.

Ocean Thermal Energy Conversion technologies are costly and difficult. OTEC projects are being financed by various authorities such as department of non-conventional and renewable energy.

Principle Of OTEC

The Ocean water gets heated up naturally due to solar radiation. The temperature of water near surface is higher than that of deep water. Ocean Thermal Gradient principle of thermodynamics is used to extract the heat energy from the Ocean.

Types of OTEC system

The types of OTEC systems are

1. Open cycle (Claude cycle, Steam cycle)

2. Closed cycle (Anderson cycle, Vapour cycle)

Both Open and Closed System OTEC, or Ocean Thermal Energy Conversion use the temperature difference between warm surface waters and deep, cold waters to create a pressure difference in a gas that can then be used to generate electricity.

Open cycle

In open system OTEC, cold water is used to reduce pressure in part of the system so much that warm surface water actually boils into a vapor at about 80°F. The warm ocean water is converted into steam in an evaporator. The steam drives steam turbine generator to deliver electrical energy.

The water vapor travels from the high pressure warm side of the system, through a turbine to drive a generator, and into the low pressure cold side of the system where the vapor condenses into desalinated water. The big advantage of open system OTEC is that the desalinated water effluent has multiple uses, especially drinking water, and can increase economic efficiency by over 30%.

Closed cycle

Rather than boiling water to make steam, closed system OTEC uses one of several refrigerants that boil and create pressure when exposed to the warmth of surface waters, and condense and lose pressure when exposed to cold temperatures from deep water.

In closed cycles, the ocean thermal energy is given to liquid working fluid (Ammonia, butane or freon). Vapour of the working fluid drives vapour turbine generator to generate electrical energy.

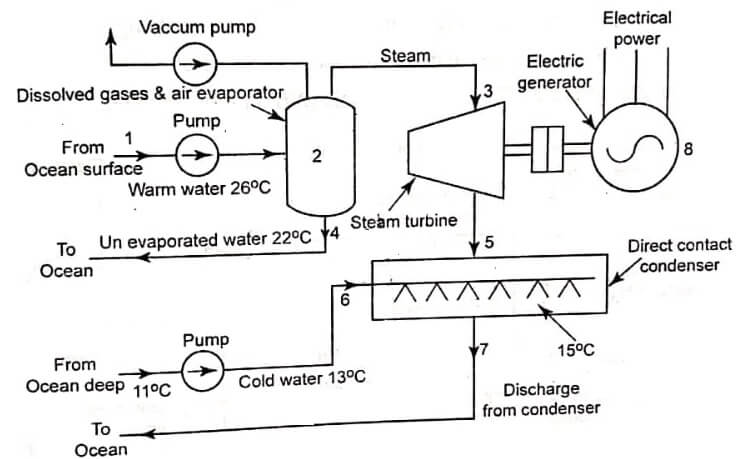

Open Cycle (Steam Cycle OTEC)

Warm Ocean water is converted into flashed steam in an evaporator. Specially designed steam turbine drives electrical generator. Steam is condensed in a contact condenser. Condensate is discharged into sea in an open cycle.

Working:

In this OTEC, warm water from ocean surface (1) (at about 26°C) is admitted into the evaporator (2). The at evaporator is maintained vacuum pressure by means of vacuum pump. At low vacuum pressures, the boiling point of water reduces and more steam is generated.

Steam generated in evaporator enters into a special steam turbine and the remaining water from evaporator is discharged into the sea.

Steam-turbine converts thermal energy into mechanical energy. Steam at (3) is comparatively at low pressure and high specific volumes as compared with conventional power plants.

The steam admitted in steam turbine (3) drives the steam turbine rotor and is exhausted (5) in condenser.

Exhaust steam from turbine is condensed and discharged into the ocean at 7°C. Cold water from deep sea is admitted into the condenser at (6). The temperature of cold water is about 15°C.

Limitations of open cycle OTEC system:

- Turbine is physically large.

- Cost of plant is high.

- Very large flow of ocean water in terms of mass and volume.

- Plant is subjected to ocean storms high waves, etc.

Closed Cycle OTEC

In a closed cycle OTEC plant, working fluid of low boiling point circulates in a closed cycle comprising of heat exchanger, vapour turbine, surface condenser and liquid vapor pressuriser. Working fluids used in closed cycle OTEC are Ammonia (NH3) Freon, Butane.

Working: In this type, working fluid (say Ammonia, NH3) is circulated through the closed cycle comprising

- Heat exchanger (3)

- Vapour turbine (4)

- Vapour condenser (6)

- Liquid pressuriser (9)

The working fluid extracts heat from the warm ocean water and is vapourised. The vapours having thermal energy are expanded in the vapour turbine (4). This vapor turbine drives electrical generator rotor (5) and the power is produced.

The expanded vapours from the turbine are condensed in cthe ondenser. Liquified working fluid is passed through pressuriser (9) into the heat exchanger (2). The working fluid is circulated again and again through the closed cycle.

Hybrid OTEC

Other systems combine closed system OTEC with open system OTEC to form a Hybrid system that can offer some of the advantages of each system. The essence of both open and closed system OTEC is that they bring cold water from the depths and use it with warm surface waters to generate energy.

Another option is to combine the two processes together into an open-cycle or closed-cycle hybrid, which might produce both electricity and desalinated water more efficiently. In a hybrid OTEC system, warm seawater might enter a vacuum where it would be flash-evaporated into steam, in a similar fashion to the open-cycle evaporation process. The steam or the warm water might then pass through an evaporator to vaporize the working fluid of a closed-cycle loop. The vaporized fluid would then drive a turbine to produce electricity, while the steam would be condensed within the condenser to produced desalinated water.

Advantages of OTEC

Environmental friendliness : Both open and closed system OTEC reach down about two thousand feet to the cold depths of the ocean. These systems will either involve power generating ships and power cables leading ashore, or they will be shore based facilities with large cold water intake pipes running along the ocean floor.

Cost : OTEC power has historically been expensive because low temperature differences mean low system efficiencies; which translates to a lot of money spent on equipment for a low power output.

Availability : The most economical areas are those with high differences in temperature between surface waters and deep waters. These areas are found in the tropics in areas extending to about 20 degrees north or south of the Equator.

Aesthetics : Either open or closed system OTEC could be used in either onshore or offshore systems.

Clean energy production : OTC has remarkably little adverse environmental impact, especially compared with other energy sources of comparable size.

Fresh water production : OTEC plants can produce fresh water as well as electrivity. Open- cycled and hybrid plants can directly produce fresh water as well as electricity and closed-cycle plants can produce similar volumes by condensation from the atmosphere.

Continuous power : Unlike most other sources of renewable energy which vay with weather and time of day, OTEC power plants can produce electricity 24 hours a day, 365 days per year.

Energy independence : OTEC plants built on the coast or moored offshore could provide enough power and water to make tropical areas independent of costly fuel imports;

Worldwide applicability : Production of fuel, such as hydrogen, by tropical Ocean Thermal Energy Conversion plants can provide the benefits of low-cost OTEC power to the whole world.

Mineral extraction : OTEC systems could provide the opportunity to mine for some of the elements in the ocean water solution.

Disadvantages

Low efficiency : The small temperature difference between the heat source (warm surface water) and the heat sink (cold deep water) temperature gives a OTEC plants a typical thermal to electrical energy conversion efficiency of less than 3 percent.

High capital costs for initial construction : About 75% of the capital cost of current OTEC designs will be for the deep seawater pipeline.

| Read More Topics |

| Hydro electric power plant |

| Diesel power plant |

| Voltage regulation in power system |