Pin and Button Locators

This is one of the common methods of pin locating. A round pin or button is used to support the job firmly and holds it in position. The main difference between pins and buttons is in length. Buttons are generally shorter in length than pins and are generally used for vertical locations. Pins are generally used for horizontal locations. Larger sizes are sometimes referred to as plugs. Shows some of the standard buttons and pins commercially available and commonly used.

Cylindrical locating pins

A cylindrical pin used to locate a workpiece from a hole produced by previous operations. In these pins, the locating diameter of the pin is made a push fit with the hole in the workpiece. The top portion of these pins is given a sufficient lead by chamfering.

Shows the cylindrical pin locators with round edge top and flange or collar at bottom. Shows a long cylindrical pin locator for long workpiece.

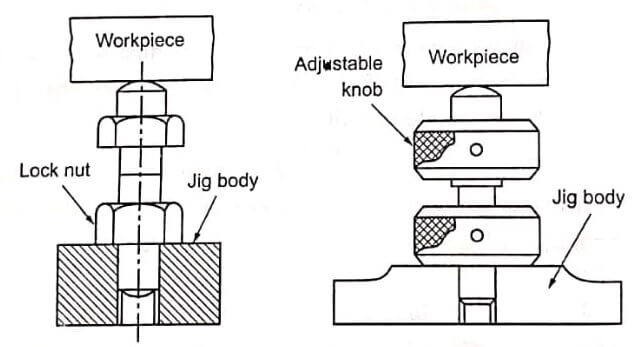

Adjustable pin locating

Adjustable pin locators are used when the surface is rough uneven, such as in castings, forgings or non-machined faces. Shows two types of adjustable pin locators.

Jack pin locating

It is another type of pin locator for locating workpiece which have variations in dimensions. There are two types of jack pins available shows a spring type jack pin. This type of jack pin is raised upward due to the spring pressure.

Therefore, it positions itself automatically according to the need. Once it attains the proper relative position, it is locked by means of a lock nut provided on one side of the pin. A key way is milled on the other side of the pin, in which another locking screw is provided to tighten the pin against the lock nut. It prevents the jack pin from rotating and falling down lock nut provided on one side of the pin. A key way is milled on the other side of the pin, in which another locking screw is provided to tighten the pin against the lock nut. It prevents the jack pin from rotating and falling down.

Shows a wedge type jack pin in which the pin is raised upward by moving the wedge horizontally in forward direction. Here, there are no springs. Instead of a spring, a wedge is provided for adjusting the pin height. This is operated manually. Hand nut is provided in one side of the pin tc push the wedge forward and a return spring is provided in other side of the pin to push the wedge back to the starting position.

If there is any deviation between centre-to-centre distance of holes or variations in size of holes, the use of two cylindrical pins will cause an error in location. Workpiece will not fit properly in location. In such cases, one of the hole is located by cylindrical pin and another by a diamond pin.

A typical diamond pin is shown. Diamond pins are relieved on two sides to allow for variation in the centre-to-centre distance of the holes. They locate at right angel to the axis between pin centres and should be placed in the largest hole. This locator facilitates easy location of the parts by seating position.

V-Locators

The workpiece having circular or semi-circular profile is located by means of V-locators provide an effective, accurate and quick means of locating such workpiece. V-locators are classified into two types

- Fixed V- locator, and

- Adjustable type V-locators

A fixed V-type locator is shown. The main part of these locators is a V-block. This V-block is fixed to the jig or fixture body by means of allen screws or dowels. It facilitates to locate the various sizes of the workpiece. If the faces of the V-block are gives, an inclination of about 30, it can be used for locating and clamping both.

(b) Adjustable type V-locators:

In adjustable type of V-locators, two V-blocks are employed, one is to fix and the other one is for sliding. The fixed V-block is used to locate the workpiece at one end whereas the sliding V-block is used to hold or clamp the workpiece at the other end. Two types of adjustable type V-locators are shown.

In figure, adjustable or sliding V-blick is operated by a hand nut mounted on a screw. The hand nut is provided with a collar which extends into a slot made in the body of the sliding V-block.