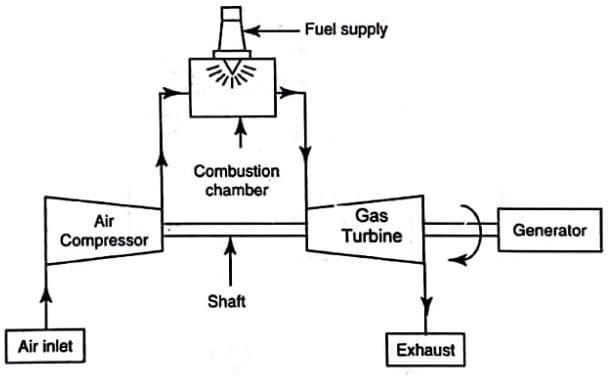

Working of Open Cycle Gas Turbine

The most basic gas turbine unit is one operating on the open cycle in which a rotary compressor and a turbine are mounted on a common shaft as image.

Air is draw from the atmosphere into the compressor and compressed to pressure of 300 to 400kN/m². The compressed air is then entered into the combustion chamber where the energy is supplied by spraying fuel into the air and ignited by hot gases. The hot gases expand through the turbine to produce the mechanical power. Then the burned gases are exhausted to the atmosphere. Then fresh air is drawn into the compressor for the next cycle.

The process is repeated again and again. Here, the compressor is driven by turbine itself. In order to achieve the network output from the unit, the turbine must develop more gross work output than the work required to drive the compressor and to overcome mechanical losses in the drive.

Working of Closed Cycle Gas Turbine

It consists of a compressor, combustion chamber, gas turbine and pre cooler. The schematic diagram of a closed cycle gas turbine plant is shown in fig.

In a closed cycle gas turbine, the air is compressed in air compressor isentropically to a required pressure and then passed through a combustion chamber where fuel injects to the air and ignited.

The high temperature air from combustion chamber expands through a gas turbine where the heat energy is converted into mechanical energy. Then the exhaust gas from the gas turbine is passed through a pre cooler where it is cooled at constant pressure with the help of circulating water to its original pressure. Then the same air is passed through the compressor again and again.

It is thus obvious, in a closed cycle gas turbine, the same air is continuously circulated repeatedly throughout the system.

Open cycle gas turbine |

Closed cycle gas turbine |

| Advantages | Disadvantages |

| No pre cooler is required because of burned gas from gas turbine exhausted to atmosphere. | Separate pre cooler arrangement is necessary. |

| For the same power developed, the size and weight of the open cycle gas turbine unit are less. | The size and weight are more. |

| Initial cost and maintenance cost of the plant are less. | Initial cost and maintenance cost are more. |

| Combustion efficiency is more. | Combustion efficiency is less. |

| Coolant is not required, therefore, it is used for moving vehicle such as air craft, jet propulsion etc. | Coolant is required for pre cooler, therefore, it is used for stationary applications such as power generation etc. |

| The response to load variation is greater than closed cycle gas turbine. | The response to load variation is less. |

Open Cycle Gas Turbine |

Closed Cycle Gas Turbine |

| Disadvantages | Advantages |

| Part load efficiency decreases rapidly as the considerable percentage of power developed by the turbine is used to drive the compressor. | Efficiency is same throughout the cycle. |

| Turbine blades are fouled by the combustion products. | The turbine blades do not wear away, since the combustion is external. |

| Starting of the plant is difficult. | Starting of the plant is easy. |

| As direct heating is used in open cycle plant, high quality fuels are required. | Low quality fuels can be used since the combustion is external. |

| Thermal stresses are high. | Thermal stresses are low. |

| Frequent internal cleaning of the system is necessary. | No need for internal cleaning. |

| Read More Topics |

| Combined cycle nuclear power plant |

| Gas cooled reactor |

| Gas Turbine power plant |

| Supercritical water cooled reactor |