Types of Welding

Fundamental principles, types of welding, Air Acetylene welding, Oxyacetylene welding, carbon arc welding, shielded metal arc welding, submerged arc welding, TIG & MIG welding.

1.Gas welding:

(a) Air-acetylene welding

(b) Oxy-acetylene welding

(c) Oxy-hydrogen welding.

2. Arc welding:

(a) Carbon arc welding

(b) Plasma arc welding

(c) Shield metal arc welding

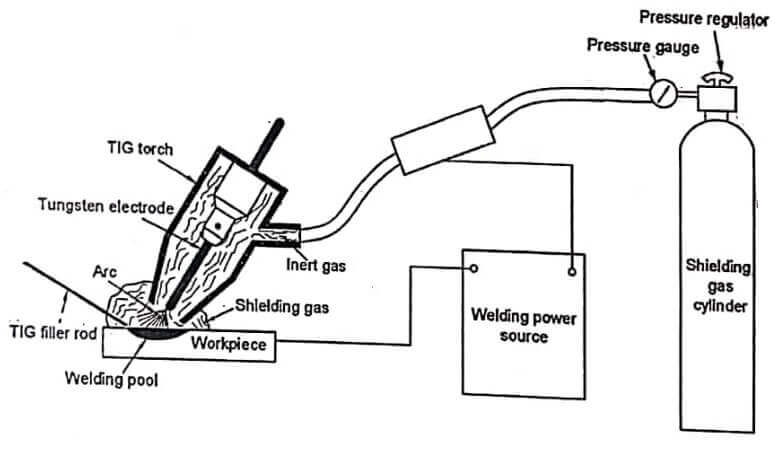

(d) Tungsten Inert Gas (TIG) welding

(e) Metal Inert Gas (MIG) welding

(f) Submerged arc welding

(g) Electro slag welding.

3. Resistance welding:

(a) Spot welding

(b) Seam welding

(c) Projection welding

(d) Resistance Butt welding

(e) Flash Butt welding

(f) Percussion welding.

4. Solid state welding:

(a) Cold welding

(b) Diffusion welding

(c) Forge welding

(d) Explosive welding

(e) Friction welding

(f) Ultrasonic welding

Types of Carbon Arc Welding Techniques

There are two types of carbon arc welding techniques.

(a) Single carbon electrode arc welding

(b) Twin carbon electrode arc welding.

In single-carbon electrode arc. welding, arc is formed between a carbon electrode and the workpiece being welded. If an arc is formed between two carbon electrodes, the technique is known as twin-carbon arc welding. Workpiece is not a part of welding electric circuit in twin carbon electrode arc welding, therefore, the welding torch may be moved from one workpiece to other without extinguishing the arc.

The technique of single-carbon arc welding uses a DC power supply which is connected using a straight polarity workpiece is connected to positive terminal and electrode to negative terminal. This technique was a favorite one when welders are needed to work with galvanized sheet metal because the heat is produced when welding could be concentrated on one general area and lessen the amount of distortion that the metal is experienced.

- Low cost of equipment and welding operation are ensured.

- High level of operator skill is not required.

METAL INERT GAS (MIG) WELDING

MIG welding is also called Gas Metal Arc Welding (GMAW) . In this arc welding, the electric arc is produced between a consumable metal wire electrode and the workpiece.

Argon, helium, CO2, argon-Oxygen or other gas mixtures are used as the inert gas. The surrounded inert gas protects the weld from atmosphere.

Consumable electrode wire having chemical composition similar to the parent material is continuously fed from a reel to the arc zone through feed unit. The arc heats and melts both workpiece edges and electrode wire. The fused electrode material is supplied to the surfaces of the workpieces, fills the weld pool and forms joint. Due to automatic feeding of the filling wire (electrode), the process is referred to as a semi-automatic. The operator controls only the torch positioning and speed.

There is an electrode holder in which the non-consumable when the are is produced. By supplying the electric tungsten electrode is fixed the inert power between electrode and workpiece, gas from the cylinder is passed through the nozzle of the welding head around the electrode. The inert gas (Argon, Helium, Nitrogen and CO;) surrounds the arc and it protects the weld from atmospheric effects and hence, defect free joints are made.

Filler metal may or may not be used. When a filler metal is used, it is usually fed manually into the weld pool. An electrode used in this process is tungsten. It has high melting point (3430°C). Therefore, it will not be melted during welding. Nozzle (shield) size, gas flow rate, filler rod size, electrode diameter and current are chosen depending the weld and metal thickness. on position of

Here energy is supplied by a constant current welding power source. This power supply produces energy which is conducted through a column of ionized gas accompanied by metal vapour known as plasma.

- TIG torch or TIG hand piece

- Power transformer

- Shielding gas cylinder

- Work clamp

SUBMERGED ARC (SAW) – Types of Welding

When the flux is required continuously supplied, on that time the flux is or where the large quantity of flux has to be used in the form of wire wound on a rotating drum or reel called flux core.

It is separately supplied instead of using welding rod along with flux material. Flux is mainly used to avoid oxidation reaction with oxygen present in the atmosphere. If the flux is used along with filler material in the form of coated electrodes, the oxidation reaction may not be completely prevented. In order to avoid oxidation reaction completely, enough quantity of flux should be supplied with a separate control independently with filler material.

Submerged arc welding is also called sub arc welding or hidden arc welding. In this welding, the complete welding setup is dipped in the flux powder and hence, it is named as submerged arc welding. In this type of welding, an electric arc is produced between consumable bare electrode and workpiece.

The metal electrode is continuously fed from the reel by a moving head. The flux powder is fed in front of the moving head. It is supplied from a hopper. When the arc is produced in the welding zone at the end of the electrode the arc is completely covered by flux powder. So, there will not be any defect in the weld due to atmosphere effects.

Materials suitable for MIG welding

MIG welding is a welding process that can weld_almost any metal. This process is versatile and can be used. with a wide variety of metals and alloys including aluminum, copper, magnesium, nickel, many of their alloys as well as iron and most of its alloys. It may not always be the best choice for weld quality but MIG welding is a fast and cost efficient.

This welding produces results that’ are more than acceptable for most manufacturing and fabrication needs.

The three most common metals welded with a MIG welder are as follows: types of welding

>Carbon steel

>Stainless steel

>Aluminum with a special feeder because aluminum wire is very soft.

Drop transfer: In this type, filler metal is transferred from the electrode to the work when discretc drops are moved across the arc gap under the influence of gravity or electromagnetic forces. Drop transfer can be either globular or spray type.

Shape, size, direction of drops and type of transfer are determined by a number of factors. The factors having the most influence are as follows:

>Magnitude and type of welding current

>Current density

>Electrode composition

>Electrode extension

>Type of shielding gas

>Power supply characteristics.

PLASMA ARC WELDING

Conventional methods are not suitable for machining metals such as cast alloy, Waspaloy alloy and carbides having promising applications in various industries also machining these materials in conventional methods causing increased machining cost. So, these types of materials in special welding methods are preferred. It will increase the productivity, reduces number of rejected components and achieves close tolerance.

Principle :

Plasma is high temperature ionized gas. A plasma is the gas region in which there is practically no resultant charge, i.e., where, positive ions and electrons are equal in number.

Types of Plasma Arc Welding

There are two types plasma arc welding used practically. They are as follows:

- Non-transfer type, and

- Transferred type.