Types of jig and fixture

There are so many types of jig and fixture. It is difficult to classify them into a standard system. However, depending upon their construction and method of operation, jigs can be broadly classified as follows:

- Boring jig

- Drill jig

- Template jig

- Plate jig

- Sandwich jig

- Latch or leaf jig

- Channel jig

- Box jig

- Post jigs or Angle plate jig

- Angular post jig

- Turnover jig

- Pot jig

- Solid jig

- Trunion jig

- Indexing jig

- Universal jig

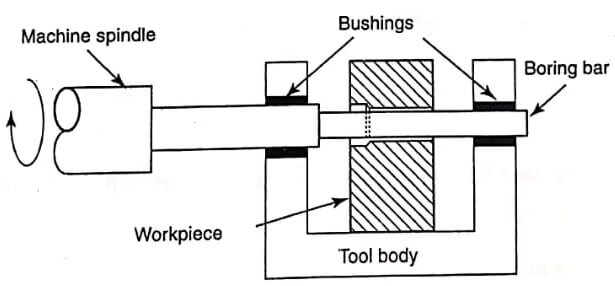

Boring Jig

Boring jigs are used to bore holes that may be too large to drill or must be made an odd size.

Drill Jig

These are used to drill, ream, tap, chamfer, counter-boring, countersink, reverse spot face or reverse countersink. The basic jig is almost the same of other machines. The only difference is in the size of the bushings used.

types of jig and fixture Drill jigs may be divided into two types.

- Open jig

- Closed jig

Open jig: These are used for simple operations where work is done on only one side of the part.

Closed jig: Closed jigs are used for parts to be machined more than one side.

Template Jig

Template jigs are normally used for accuracy rather than speed. This type of jig fits over, on or into the work and is not usually clamped temples. Templates are least expensive and the simplest type of jig to use. They may or may not have bushings. When bushings are not used, the whole jig plate is normally hardened.

Plate Jig

The plate type of jig mainly consists of a single jig plate or bush plate with a provision for clamping and location. This is the simplest type of jig used for mass production Industries. A typical design of such a jig is shown in Figure. The workpiece is located by a few number of locating pins and clamped by two knurled screws against the location pins. The workpiece should be supported adequately against bending due to the downward thrust of the drill. There should be an enough clearance below the workpiece for overshoot of the drill after passing through the workpiece.

Sandwich Jig

These jigs are in the form of plate jig with a back plate. This type of jig is ideal for thin or soft parts that could bend or wrap in another style of jig. Here again, the use of bushings is determined by the number of parts to be made.

Latch or Leaf Jig

It has a leaf plate which is capable of swinging about a fulcrum point so that it can open or close to load or unload the workpiece. After locating the workpiece inside the jig, the leaf plate is firmly closed and locked by means of an eyebolt. The open slot in the jig plate and swinging eyebolt facilitate a quick clamping and unclamping the jig plate.

Leaf jigs are suitable for complicated workpiece with irregular contours. Holes may be drilled more than one surface for a single loading of the jig.

The disadvantage of leaf jig is that chips may accumulate inside and cause trouble unless provisions are made for them. Also if the drill bushings are fitted in the leaf, play in pivoted end may affect drilling accuracy.

Channel Jig

These are named after their shape, such as a channel with a bush plate at the top. The channel is made either by machining a solid cast iron piece or by fabricating from mild steel plates.

These jigs usually of open type are shown in Figure. Sometimes, it may also be provided with a swinging leaf to form a channel and leaf jig, as shown in Figure.

Box Jig

Figure shows a box jig which is used when holes are to be drilled more than one faces of the workpiece. The jig body is generally shaped, such as a box with one side open for loading and unloading the workpiece. The open side is provided with a hinged latch which often houses bushes and clamping screws. The jig is fitted with bushes on various sides and suitable jig feet on the opposite side to provide a good a seating.

After one face is drilled, the next side may be drilled by simply flopping the jig to expose this side to the drill spindle. The advantage of box jig is that greater accuracy can be maintained and less part handling is necessary. The body of the jig is made as light as possible to reduce fatigue during flopping.

Post Jigs or Angle Plate Jig

The post jig shown in Figure is used for drilling and reaming operations. It is named so because it has a solid post to locate the workpiece from its bore. Therefore, these jigs are mainly useful for hollow workpieces. The workpiece is clamped by using end nut and C-washer, as shown in Figure. Burr grooves are provided to facilitate and overshoot the drill after passing through the workpiece. C-washer is used for easy unloading of workpiece without removing the hand nut fully. A flattered pin is used to facilitate easier angular location of the workpiece.

Figure shows a post jig with vertical position of location post. These jigs are used to locate the workpiece from its bore by means of a post which is also used to locate the drill plate. The swing washer enables the drill plate to be removed without removing the hand nut. Sometimes, the location post is integrated or rigidly fixed with the base.

Angular Post Jig

Figure shows an angular post jigs. These jigs are used to drill holes in the workpiece at some angles. The drill bush is extended and shaped to prevont drill run, and yet allow removal of the workpiece. The clamping nut is one of the quick action types because of easy removal of workpiece.

- See More : Locating and clamping principles

- See More : NC machine tool fixture

- See More : Principles of clamping