Petrol vapours from fuel tank escape into atmosphere by evaporation (or breathing). This vapour comes out through filter cap vent or the tank vent tube. When the engine is not running, petrol will evaporative emission control system leak in the carburettor float chamber. It is estimated that the losses from the fuel tank are about 10% of the total hydrocarbon emission.

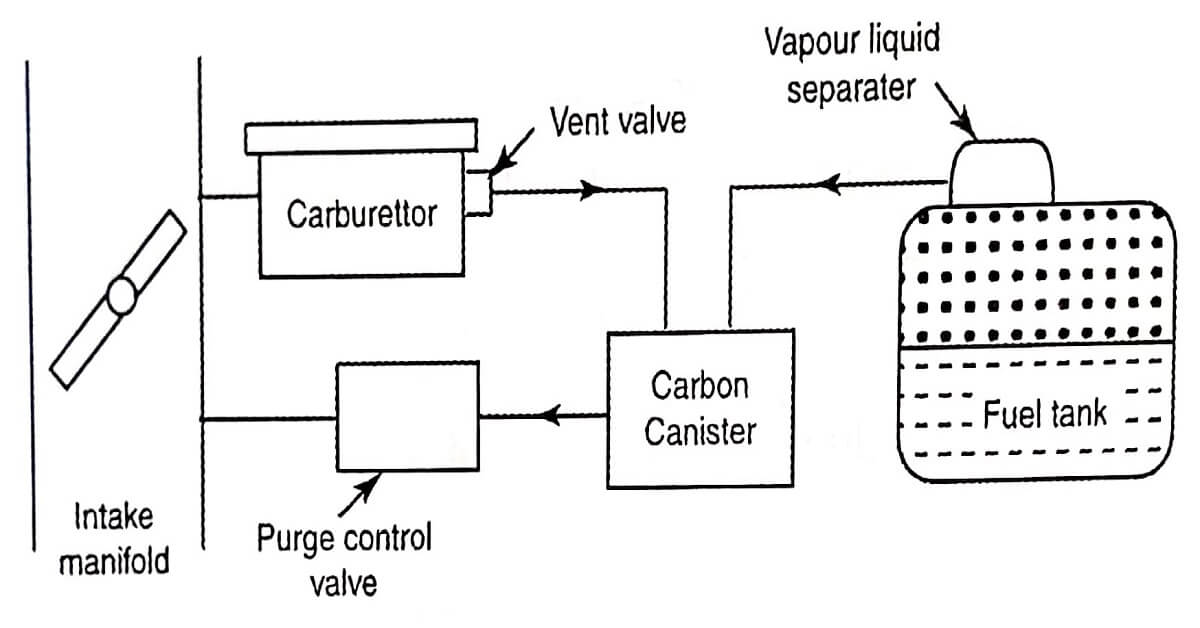

A simple system to control these losses is shown in fig. In this, fuel tank and carburetor float chamber are vented to a carbon canister. The

canister absorbs the vapour and stores it. “Absorb” means the petrol vapours are trapped by stricking to the outside of the charcoal particles.

A vapour liquid separator is provided on the top of fuel tank. Vapours go to the tap of the separator while liquid petrol is returned to the tank. The separator is filled with filter material that allows vapour, but not liquid to pure. Fig shows a float type separator in which the float goes up and closes the orifice to the canister hose.

Carburetor float bowl has two vents. One is connected to the air cleaner and helps to compensate a clogged air cleaner. The other vents connect to the charcoal canister. Various arrangements may control this vent.

A special filter cap is provided on the fuel tank which maintains some pressure in the tank, that forces fuel vapors from the tank to the canister.

Flow of vapours from the fuel tank may be controlled by a mechanically operated vent valve or an electrically operated solenoid valve. The throttle linkage operates the mechanical valve. By that, it allows the vapours from float chamber to canister during idling.

When the throttle is opened, the vent valve is closed. Likewise the electrical vent valve is opened with the ignition switch off. When the

ignition switch is on the vent valve is closed by the energization of solenoid.

When the engine is operated, the fresh vapor enters through the canister and picks up the petrol vapour from the carbon in the canister. This air then flows into the intake manifold and becomes part of air fuel mixture entering the engine cylinders to be burnt there. This action of clearing the trapped petrol vapour from the canister is called purging.

Some evaporative emission control system leak have the purge valve in the purge line. It connects to the throttle body and discharges vapours just above the throttle valve into the intake air.

Evaporative Emission Control System for C.I Engine

The fuel injection system of IC engine has no float bowl. Therefore, the evaporative control system is used only fuel vapour from the fuel tank. Fig illustrates the system of evaporative emission control system for C.I engine. In this, the canister has two connections. One is the connection to fuel tank, the other is the purge line to the throttle body.

Instead of a vacuum operated purge valve, an electric purge control solenoid may be used. It is mounted on the canister or in the purge line.

Crankcase emission control

Engines have some blow. It is mostly got past the piston ring and into the crank case. To remove these, air is circulated through crank case when the engine is running. This is called crank case ventilation. The crank case ventilation system prevents build up and oil leakage.

In addition, it removes blow by gas to prevent the formation of corrosion and sludge (sludge is a thick, creamy, black substances that can form in the engine. It clogs oil screens and lines thereby preventing oil circulation).