Mechatronics engineering is a word originated in Japan in 1980s to denote the combination of technologies which go together to produce industrial robots.

The word, mechatronics, is composed of “mecha” from mechanism and the “tronics” from electronics. In other words, technologies and developed products will be incorporating electronics more and more into mechanism, intimately and organically, and making it impossible to tell where one ends and the other begins.

According to the Mechatronics Forum, UK a formal definition of Mechatronics is “the synergistic integration of Mechanics and Mechanical Engineering, Electronics Computer technology, and IT to produce or enhance products and systems.”

W.Bolton defines mechatronics as “A mechatronic system is not just a marriage of electrical and mechanical systems and is more than just a control system: it is a complete integration of all of them.”

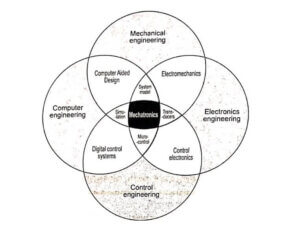

A graphical representation of mechatronics, illustrates integrated and inter-disciplinary approach of nature.

Even though many people believe that the presence of mechanical, electrical, electronic components, and computers make a system mechatronics, others do not feel the same as there is nothing wrong with the individual identity.

Hence, the term mechatronics should be used to represent a different meaning, namely, “a design philosophy,” where mechanical, electrical, electronics components, and IT should be considered together in the design stage itself to obtain a compact, efficient, and economic product rather than designing the components separately.

The concept of mechatronics is very important today to meet the customers” ever increasing demands and still select mechanical devices, sensors and actuators, analog and digital circuits, microprocessor based components, and control devices such as logic gates to design modern systems.

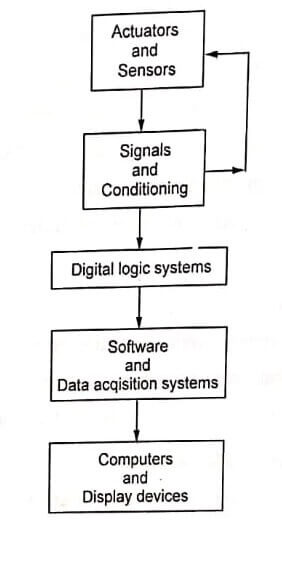

Elements of Mechatronics Engineering Systems

Various elements in typical mechatronic systems are described here under.

- Actuators and Sensors

- Signals and Conditioning

- Digital Logic Systems

- Software and Data Acquisition systems

- Computers and Display devices.

Sensors and Actuators

Sensor and actuators mostly come under mechanical systems. The actuators produce motion or cause some action. The sensors detect the state of the system parameters, inputs and outputs.

The various actuators used in mechatronic system are parametric and hydraulic actuators, electro mechanical actuators, electrical motors such as D.C motors, A.C motors, stepper motors, servomotors, and piezoelectric actuators.

The various types of sensors used in mechatronic system are linear and rotational sensors, acceleration sensors, force, torque, and pressure sensors, flow sensors, temperature sensors, proximity sensors, light sensors.

Signals and Conditioning

The mechatronic systems deal with two types of signals and conditioning: input and output. The input devices receive input signals from the mechatronic systems via interfacing devices and sensors, and then send to the control circuits for conditioning or processing.

The various input signal conditioning devices used in mechatronic system are discrete circuits, amplifiers, analog-to-digital (A/D) convertors, Digital to digital (D/D) convertors.

The output signals from the system are send to output/display devices through interfacing devices. The output signals from the system are send to output/display devices through interfacing devices.

The various output signal conditioning devices through interfacing devices. The various output signal conditioning devices used in mechatronic system are digital to analog (D/A) convertors, display decoders (DD) convertors, amplifiers, power transistors, power op-amps.

Digital Logic Systems – Digital logic devices control overall system operation. The various digital logic systems used in mechatronic system are logic circuits, microcontrollers, programmable logic controllers, sequencing and timing controls, control algorithms.

Software and Data Acquisition systems

Data acquisition system acquires the output signals from sensors in the form of voltage, frequency, resistance etc. and inputting into the microprocessor or computer.

Software is used to control the acquisition of data through DAC board. The data acquisition system consists of multiplexer, amplifier, register and control circuitry, DAC board.

The various data acquisition systems used in mechatronic system are data loggers, computer with plug-in boards etc.

Computers and Display devices – Computers are used to store large number of data and process further through software.

Display devices are used to give visual feedback to the user. The various display devices used in mechatronic system are LEDs, CRT, LCD, digital displays etc.

Types of Mechatronics Systems

Japan Society for the Promotion of Machine Industry (JSPMI) classified mechatronics products into following four categories:

Class I : Primarily mechanical products with electronics incorporated to enhance functionality.

Example: NC machine tools and variable speed drives in manufacturing machines.

Class II : Traditional mechanical systems with significantly updated internal devices incorporating electronics. The external user interface are unaltered.

Example : Modern sewing machine and Automated manufacturing systems.

Class III : Systems that retain the functionality of the traditional mechanical systems, but the internal mechanisms are replaced by electronics.

Example: digital watch, automatic camera.

Class IV : Products designed with mechanical and electronic technologies through synergistic integration.

Example: Photocopiers, intelligent washers and dryers, rice cookers, and automatic ovens.

Examples of Mechatronics Systems Engineering

Examples of mechatronics engineering systems are as follows:

- NC & CNC machine tools, variable speed drives, fiexible manufacturing systems (FMS) & automated manufacturing systems, automated guided vehicles, rapid prototyping & robots.

- Computers disk drives

- Photocopiers, Laser printers & fax machines

- VCR/DVD drives

- Automatic washing machines, dish washer, rice cooker, automatic ovens & modern sewing machines

- Automatic teller machine (ATM)

- Coin counter

- Automatic/digital camera, digital watch.

- Aircraft flight control systems such as cockpit control, landing gear control etc.

- Automobile applications include electronic engine management system, collision detection, global positioning system, antilock brake systems, keyless entry system, cruise control, parking assistance system and others.

- Medical diagnostic instruments such as CT scan system, automatic blood testing equitpment,etc.

- Automatic sliding door, vending machines, and garage door openers.

- Aerospace applications include launching, satellite solar plate extending mechanisms, and many more.

Advantages and Disadvantages of Mechatronics Systems

Advantages

- Cost effective and good quality products

- High degree of flexibility to modify or redesign

- Very good performance characteristics

- Wide area of application

- Greater productivity in case of manufacturing organization

- Possibility of remote controlling as well as centralized monitoring and control

- Greater extend of machine utilization

Disadvantages

- High initial cost

- Multi-disciplinary engineering background required to design and implementation

- Need of highly trained workers

- Complexity in identification and correction of problems in the systems

Measurement Systems

The word system in mechatronics refers to a group of physical component connected or related in such a manner as to form as entire unit for performing a specific task.

For example, this universe is a system consists of large number of subsystems. Similarly human body is a system consists of large number of subsystems such as brain, nerve systems, digestive systems etc.

All mechatronic devices consist of various systems in which some input data are given to get specified output.

A system can be treated as a black box having an input and output. For example, an electronic heater may be thought of as a system which has, as its input electric power and as output heat as shown.

A measurement system involves the precise measurement and display/recording of physical, chemical, mechanical, electrical or optical parameters. It provides a means of describing natural phenomena in quantitative terms.

Measurements system provides the input to the control systems of mechatronics. A generalized measurement system comprises of a sensor/transducer, signal processor, and a display/recording device.

Sensor or transducer : Sensor or transducer is a device which converts a physical quantity, property or condition into output, usually electrical parameters such as voltage, resistance or capacitance.

For example, a thermocouple is a sensor which converts changes in temperature into a voltage.

Signal processor : Signal processor or conditioner receives output signal from sensor or transducer and manipulates or processes into a suitable input signal to control system.

Signal processor performs filtering and amplification functions. For example, the output from the thermocouple is very small voltage, therefore, amplifier increases the magnitude of the voltage and the A/D (analog to digital) converter changes the analog voltage signal to a coded digital signal.

Display or recording device : Recorder records the output from signal conditioner and display device gives the measured variable in visual or quantitative form.

For example, LEDs, CRT, LCD are the example of display devices which gives measured variable in terms of numbers.

Example of measurement system : Consider a digital liquid level measuring system in a tank shown. This system incorporates float with resistive potentiometer as a sensor which gives electrical voltage as output depending upon the liquid level in the tank.

Signal processor involves an amplifier increases the small voltage into higher voltage.

A/D converter analogue voltage to a digital signal, and digital decoder (DD) decodes the digital data into readable format to display. LEDs display the value of liquid level in terms of specific quantity.

| Read More Topics |

| Control system |

| Traditional and mechatronics design |

| Microprocessor based controller |