Superconducting Magnetic Energy Storage – Electricity (dc) can be stored in magnetic fields, wherein the energy stored is proportional to the inductance times the square of the current. An energy storage system based on magnetic would involve an ac-dc-ac converter system (like batteries) and a large coil of a superconductor (a niobium-titanium alloy). To achieve superconductivity, the conductor is maintained in a bath of liquid helium at about 1.8 K. Since there are no moving parts in the coil and electrical resistance is near zero, efficiencies can be above 90%.

Energy losses occur in the converter and refrigeration system, although both can be designed to achieve high efficiency. The cost per unit of stored energy of superconducting magnetic energy storage (SMES) varies with the minus one third power of stored energy. In other words, cost per unit of stored energy decreases by 21% for each doubling of storage capacity. In practice, therefore, very large sizes of several thousand mega watthours are required for SMES to be cost competitive.

The basic operation of a complete SMES system is very simple and its setup is shown in fig. The transmission voltage from ac network is first stepped down from a few kilowatts to several hundred volts using a step down transformer. This is then converted into dc, which is fed into the super conducting coil.

When power flows from system to coil, the dc voltage will charge up the superconducting coil and energy is stored in the coil. When ac network requires power boost, say when there are sags, spikes, and voltage and frequency instabilities, coil discharges and acts as a source of energy. The dc voltage is converted back into ac voltage through the converter.

The maximum energy stored depends on the design of the device. SMES systems are able to store up to 10 MW. However, some research believe an SMES can potentially store up to 2,000 MW. Theoretically, a coil of around 150 to 500 m radius would be able to support a load of 5000 MWh at 100 MW depending on the peak field and ratio of the coil’s height and diameter.

SMES is, however, attractive for applications where high power is required for very short periods. For example, a small 10- MW, 3-s experimental system was built to inhibit sub-synchronous resonance in a high-voltage ac line from the state of Washington to California.

Through R&D, superconducting magnetic energy storage (SMES) costs might be reduced sufficiently to become competitive for bulk storage application. Ongoing research is directed to improving conductor current density and developing innovative design concepts that lower conductor support requirements.

High Temperature Superconductor (HTS) coils of Ag-clad (Bi, Pb)2 Sr2 Ca2 Cu3 O10+x material, which can be operated with liquid nitrogen are commercially available. With successful research, issues involving the effects of magnetic fields, land use, and quality control suggest that the practical systems are commercially available and operational. A typical bidirectional converter with cryogenic arrangement is shown in fig.

Ultracapacitor – Capacitors are some of the most essential building blocks of electronic circuits to hold dc voltages. Based on the same principle, but on a much larger scale, it is conceivable that capacitors could be used to store energy for extended periods of time.

Until some time ago, however, capacitors only managed to hold very little energy compared to a regular battery. In 1997, researchers from CSIRO developed the first supercapacitor. This is basically a capacitor which is able to hold significantly more charge using thin film polymers for the dielectric layer.

The electrodes are made of carbon nanotubes. The energy density of a normal capacitor is only 0.5 Wh/kg. PET super capacitors can store 4 times more energy compared to the normal capacitor. Carbon nanotubes and polymers are practical for supercapacitors. Carbon nanotubes have excellent nanoporosity properties allowing the polymer tiny spaces to sit in the tube and act as a dielectric.

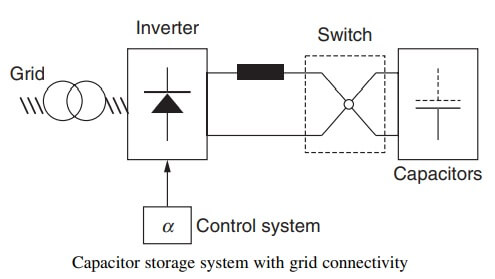

Polymers have redox (reduction-oxidation) storage mechanism along with a high surface area. There are researches going on to replace carbon nanotubes with ceramics for their superconducting properties. These promising technologies introduce potential to improve the energy storage and represent a new generation of electrochemical components with very high capacitance for energy storage. A capacitor storage system with grid interface is shown in fig.

Supercapacitors are well suited to replace batteries in many applications. This is because at the moment their scale is comparable to that of batteries, from small ones used in cellular phones to large ones that can be found in cars. Even though supercapacitors have a lower energy density compared to batteries, they avoid many of the battery’s disadvantages.

Batteries have a limited number of charge/discharge cycles and take time to charge and discharge because the process involves chemical reactions with noninstantaneous rates. These chemical reactions have parasitic thermal release that causes the battery to heat up. Batteries have a limited life cycle with a degrading performance and acidic batteries are hazardous to the environment. Super capacitors can be charged and discharged almost an unlimited number of times.

They can discharge in matters of milliseconds and are capable of producing enormous currents. Hence, they are very useful in load levelling applications and fields where a sudden boost of power is needed in a fraction of a second. They do not release any thermal heat during discharge. Supercapacitors have a very long lifetime, which reduces maintenance costs. They do not release any hazardous substances that can damage the environment. Their performance does not degrade with time.

Supercapacitors are extremely safe for storage as they are easily discharged. They have low internal resistances, even if many of them are coupled together. Even though they have a lower energy density, are bulkier and heavier than an equivalent battery, they have already replaced batteries in many applications due to their readiness in releasing power. Supercapacitors were initially used by the U. S. military to start the engines of tanks and submarines. Most applications nowadays are in the field of hybrid vehicles and handheld electronic devices.

In most hybrid vehicles, 42 V supercapacitors are used. General Motors has developed a pickup truck with a V8 engine that uses the supercapacitor to replace the battery. The efficiency of the engine rose by 14%. The supercapacitor supplies energy to the alternator.

In rural areas, where there are voltage sags in the power grid, supercapacitors can be used to reduce the effect of fluctuations. The supercapacitor has become available to the public. A commercial supercapacitor can hold 2,500 F, release 300 A of peak current with a peak voltage handling of about 400 V. The life cycle of this supercapacitor is more than 1×106 charge/recharge cycles.

| Read More Topics |

| Electrochemical Energy Storage |

| Automated feeder switching systems |

| Mechanical energy storage |